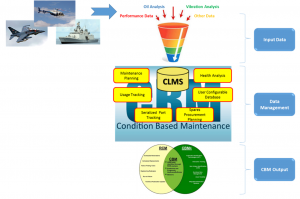

Component Life Monitoring System (CLMS) is a locally developed and customised system by employing the Condition Based Maintenance (CBM)’s methodology. It’s a smart system where it predicts to prevent a tracked component before it fails. It is also a system designed to track location, configuration, usage status, condition, and maintenance history of serialized machinery components or plant equipment in a customized reports which made the visibility of information is tremendously improved for an on-line decision making.

BENEFITS

- Machinery condition trends data to assist In predicting failures and preventing unscheduled shutdowns

- A Proactive rather than reactive approach to maintenance

- Operational cost saving

- Increase the operational readiness of the assets

- Reduce the maintenance cost

- Extending periodic maintenance and Pre-planned maintenance activity

- Reduce shop visit

- Improve equipment availability and fewer spare parts in stock

- Improve visibility of information on-line for decision making

- Schedule of manpower requirement in advance

- Effective and organised data library